⚡Flash Sale-Mini Lathe-Milling

-

Detail

Describe

Product Overview

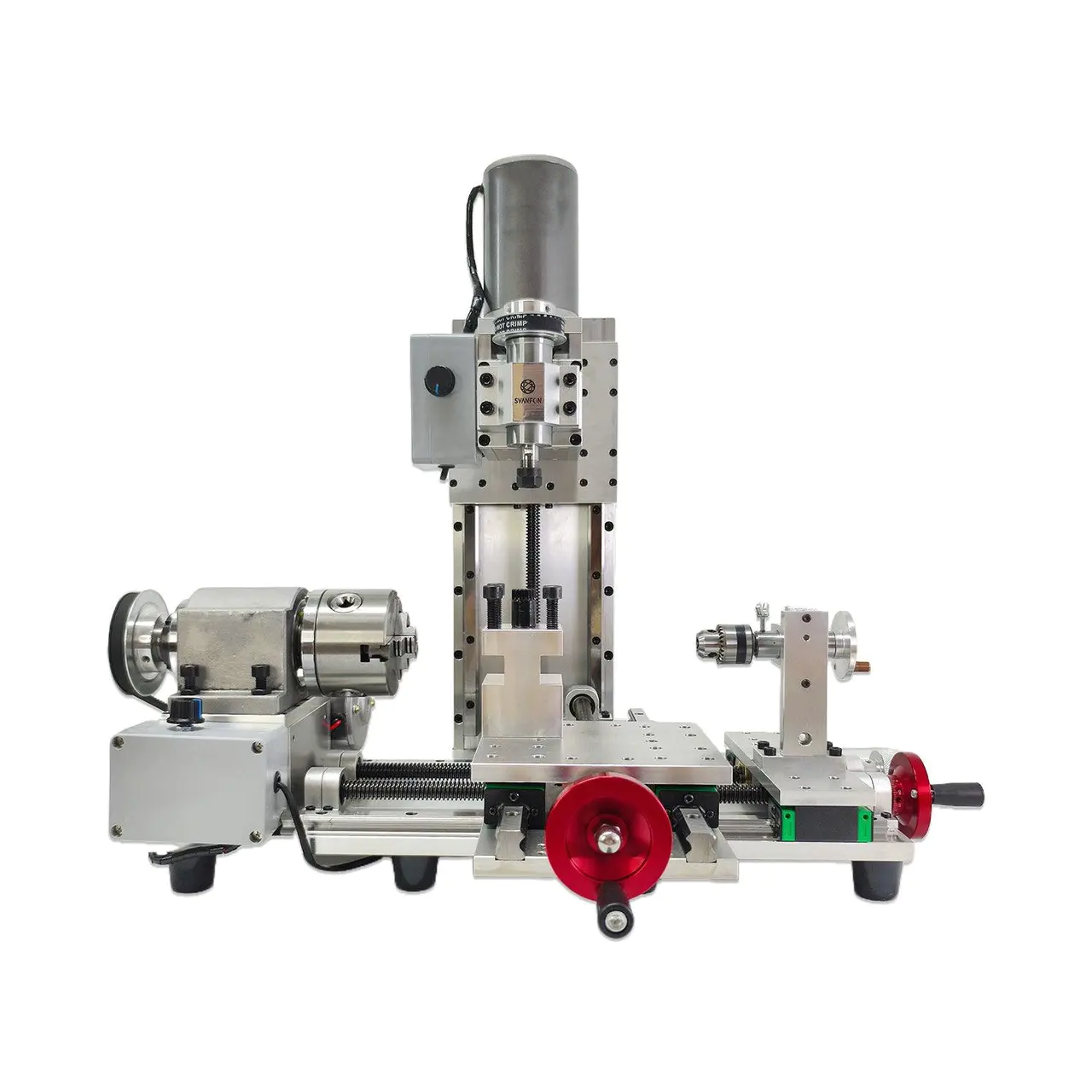

The mini lathe-milling machine is a desktop-level multifunctional processing equipment with high portability and flexibility, suitable for various scenarios.

Feature

1.Powerful processing ability

- Lathe: Equipped with a 100W motor and an 80 manual three-jaw chuck. The maximum processing diameter is 60mm and the length is 160mm. It can process various materials such as copper, iron, aluminum, 304 stainless steel, and 45 steel.

- Milling machine: Comes with a 100W motor and can process copper and aluminum.

- Capable of performing various processing operations such as turning, milling, and drilling to meet different processing needs.

2.Up grad ability

- Motor upgrade: Can be upgraded to a 200W or 350W high-torque motor to enhance processing ability.

- Whole machine upgrade: The entire machine can be upgraded to a CNC system to achieve high-precision processing operations such as threading and milling threads.

3.High play ability

Inspires users' creativity and allows for personalized processing and transformation according to different needs.

III. Product Parameters

- Product size: 610/610/510 mm (Length Width Height), weight: 33KG.

- Packaging size: Carton 550/450/200mm (Length Width Height), weight: 35KG (loose parts packaging).

- Lathe spindle motor power: 100W, input voltage AC 220V, maximum speed 4500 rpm±5%.

- Milling machine spindle motor power: 100W, input voltage AC 220V, maximum speed 4500 rpm±5%.

- XYZ travel: 140mm.

- Tail stock: Chuck size ≤4mm, stroke of chuck: 35mm, tail stock stroke: 160mm. (The chuck and tail stock can operate independently.)

- Lathe spindle: Standard with an 80 chuck. The spindle through hole is 16mm. The maximum speed is 2000rpm (adjustable speed), and the reduction ratio is 2.25.

- Turning length: ≤160mm.

- Milling machine spindle: ER11 powerless spindle. Tool size ∅1~7mm. The maximum speed is 2600rpm (adjustable speed), and the reduction ratio is 1.67.

350W vs. 680W Rotor Comparison

Feature 350W Rotor 680W Rotor Fan Diameter Standard 10mm larger with 4 more blades (better heat dissipation, longer working time) Windings & Wire Thickness Standard More windings, thicker wire (higher efficiency, greater torque) Commutator Size Standard Twice the size (more durable, stable speed, less sparking) Fixing Inserts Not included Added (prevents wire dislodging at high speeds)

Transportation Method

- In the form of parts (default way, comes with video assembly tutorials).

- Assembled finished product way

-

Customer Reviews

Go*****ef

Go*****ef

Oh, yes, after I bought this, the old master in the factory asked me if I had secretly upgraded the equipment.

A***n

A***n

¡Excelente producto! Hasta ahora estoy muy satisfecho con la precisión de cada pieza.

B***ul

B***ul

¡Excelente producto! Aunque el proceso de montaje fue largo, estoy muy contento de ver el producto terminado.

M***ma

M***ma

Operación muy precisa y suave. ¡Ideal para proyectos pequeños!

O**

O**

The screw rod reverse clearance is less than 0.03mm, which is comparable to industrial grade!

Micro***********ftsmen

Micro***********ftsmen

No need to outsource the production of model aircraft gears

E***e

E***e

Now I believe in what it means to have a small machine tool with great potential

Ro*****ein

Ro*****ein

No need to outsource the production of model aircraft gears